Yin gyaran gyare-gyaren allura yana da dalilai guda biyu;Daya shine don ƙara santsi na ƙura, ta yadda fuskar samfuran da aka samar ta zama santsi, kyakkyawa da kyau.Ɗayan kuma shine a sauƙaƙe ƙirar don lalata, don kada filastik ya makale a kan ƙirar kuma ba za a iya cire shi ba.

Kariya gaallura mpolishing sune kamar haka:

(1) Lokacin da sabon rami ya fara yin injin, za a fara bincika saman aikin, kuma za a tsabtace saman da kananzir, don kada saman dutsen mai ya makale da datti don haka ya rasa aikin yankewa.

(2) Za a nika ƙwaya mai ƙanƙara kamar yadda ake niƙa da farko da sauƙi a niƙa, musamman ga wasu matattun kusurwoyi waɗanda suke da wuyar niƙa, ƙasa mai zurfi za a fara niƙa.

(3) Wasu kayan aikin na iya samun guda da yawa da aka haɗa su don goge goge.Da farko, a niƙa ƙaƙƙarfan hatsi ko ƙyalƙyali na kayan aikin guda ɗaya daban, sannan a niƙa duk kayan aikin tare don santsi.

(4) Don kayan aiki tare da babban jirgin sama ko jirgin sama na gefe, yi amfani da dutsen mai don niƙa fitar da ƙwayar hatsi sannan a yi amfani da madaidaiciyar takardar ƙarfe don bincika watsa haske da auna don bincika ko akwai rashin daidaituwa ko ƙasa.Idan akwai wani abu da aka yanke, zai haifar da wahala wajen rushewa ko damuwa na kayan aikin.

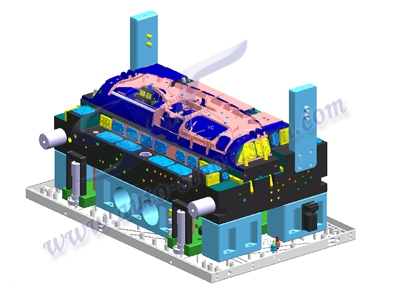

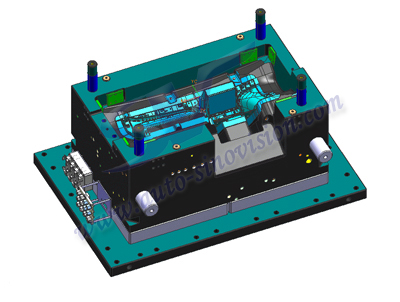

Injection gyare-gyaren masana'anta

(5) Don kauce wa kula da halin da ake ciki cewa die workpiece ya ɓullo da wani zare ko wasu bonding saman bukatar a kare, da saw ruwa za a iya amfani da manna ko sandpaper za a iya amfani da manna a gefen, don haka kamar yadda don samun kyakkyawan sakamako na kariya.

(6) Ja da mold jirgin sama da baya, da kuma sanya rike na ja whetstone a matsayin lebur kamar yadda zai yiwu, bai wuce 25 °;Saboda gangaren ya yi girma da yawa, ana bugun ƙarfin daga sama zuwa ƙasa, wanda ke haifar da sauƙi zuwa manyan layukan da ke kan aikin.

(7) Idan an goge saman kayan aikin da takarda tagulla ko takardar bamboo da aka matse shi da takarda, yashi bai kamata ya zama ya fi yankin kayan aikin ba, in ba haka ba zai niƙa zuwa wurin da bai kamata a niƙa ba.

(8) Siffar kayan aikin niƙa ya kamata ya kasance kusa da siffar mold surface, don tabbatar da cewa workpiece ba nakasu da nika.

Misali,robobin kayan aikin lantarki, filastikkwantena abinci, da sauransu. Idan abubuwan da ke sama suna da kyau, bayyanar polishing na ƙirar allura za ta yi kyau sosai.

Lokacin aikawa: Oktoba-14-2022